- Home

- About Us

- Our Services

- RIG AUDIT, INSPECTION & COMMISSIONING SERVICES

- LIFTING EQUIPMENT THROUGH EXAMINATION AND PROOF LOAD TESTING

- TUBULAR INSPECTION SERVICES

- RIG PARTS AND HANDLING TOOLS INSPECTION

- NDT INSPECTION SERVICES

- CALIBRATION SERVICE

- LIFTING ACCESSORIES SUPPLYING

- LIFTING OPERATION SUPERVISION

- TRAINING SERVICES

- ISSUED CERTIFICATES & REPORTS

- Quality

- Carrer

- Our Clients

- Contact Us

• Tools include fiberscopes, bores copes, magnifying glasses and mirrors.

• Tools include fiberscopes, bores copes, magnifying glasses and mirrors. The part is magnetized. Finely milled iron particles coated with a dye pigment are then applied to the specimen. These particles are attracted to magnetic flux leakage fields and will cluster to form an indication directly over the discontinuity.

The part is magnetized. Finely milled iron particles coated with a dye pigment are then applied to the specimen. These particles are attracted to magnetic flux leakage fields and will cluster to form an indication directly over the discontinuity.

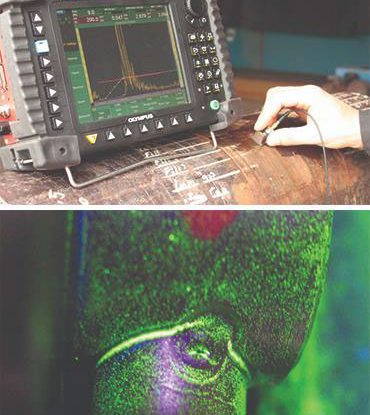

Service inspection of pipeline is a challenging yet crucial operation, particularly for pipes buried under ground.

Service inspection of pipeline is a challenging yet crucial operation, particularly for pipes buried under ground. oil and gas storage tank’s life cycle can be managed with the computing solution, which enables the construction.

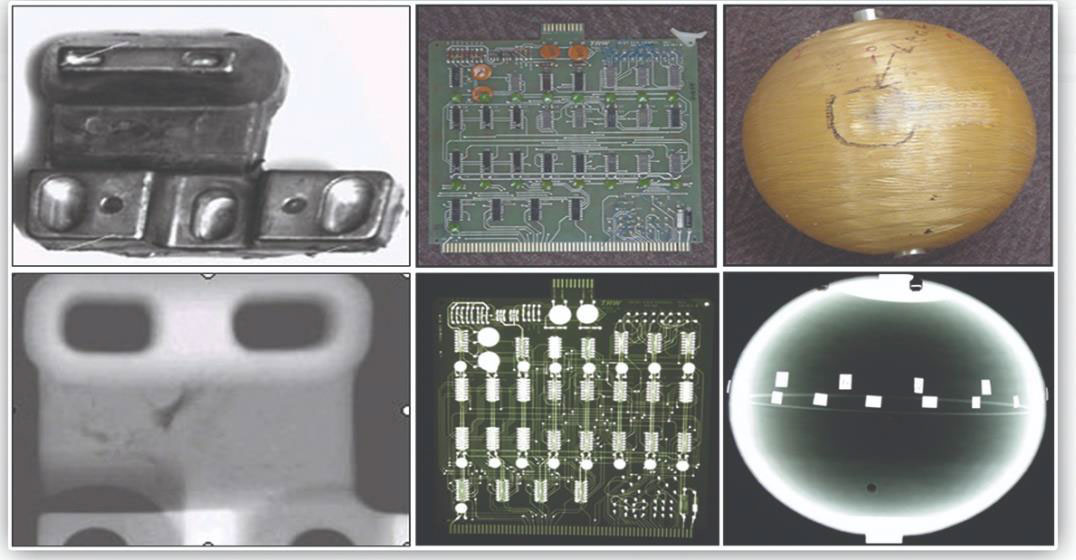

oil and gas storage tank’s life cycle can be managed with the computing solution, which enables the construction. • Ultrasonic Testing of weld metals & other components.

• Ultrasonic Testing of weld metals & other components.